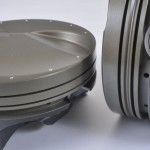

By combining hard-coat anodizing with a moly-skirt coating, Diamond’s double-coat pistons will benefit all engines but is particularly useful in power-adder applications.

Features:

• Provides a thermal barrier and increases both corrosion-resistance and wear-resistance

• Deters piston rings from micro welding themselves to the ring grooves and it creates an excellent adhesion surface

• Resists high cylinder temperatures and pressures and frees-up a little more power; baked-on molybdenum dry-film lubricant skirt coating adds an anti-friction anti-scuffing surface

• Increases machined clearances of about .002-inch on the piston diameter and also on the width and depth of the ring grooves to compensate for the additional build-up from the anodizing process

• Includes submerging in a detergent-acid bath, followed by two rinses before the anodizing process and three rinses after

• Adds five light coats of the moly dry-film lubricant and baked in an oven for an hour.

Diamond, who has been developing and testing their double-coat procedures for over two years, conducts all their coating processes inhouse.

The turn-around time for the Diamond double-coat process is about two days and the cost is $50 per piston. Single coatings, either anodizing or moly-skirt, are still available.

For more information contact us